Mechanical properties of silk

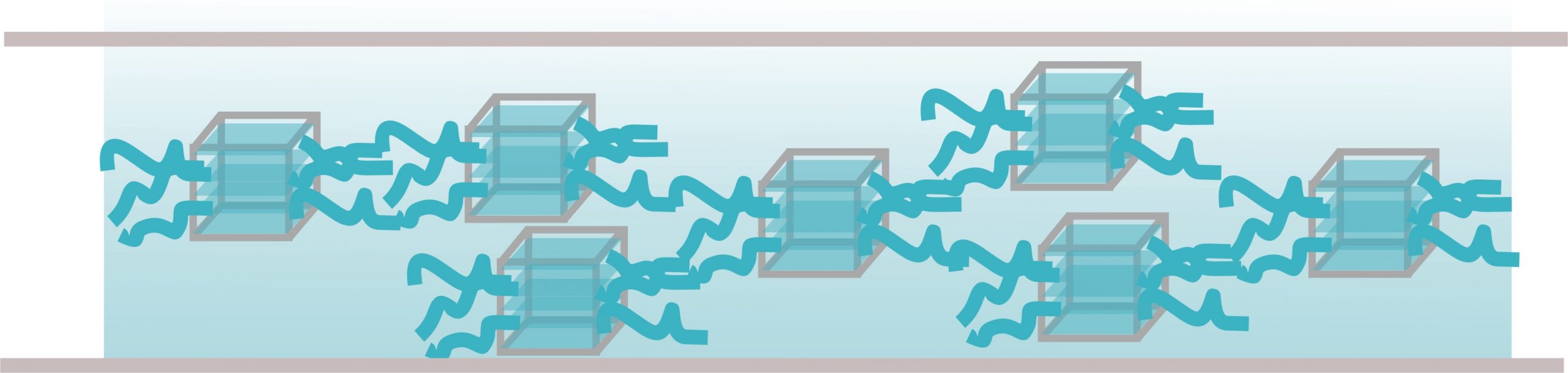

Silk is one of the many biomaterials with mechanical properties not yet reached by synthetic counterparts. Silk fibers have an outstanding toughness, that is, are very extensible while also sustaining large forces. They are exclusively made from protein in a way similar to a block-copolymer: blocks of polyalanine, assembled into stacks of beta-sheets representing nano-sized crystals, alternate with glycine-rich disordered regions forming an amorphous matrix (see scheme).

We aim at revealing the structural determinants on the nano-scale of silk’s outstanding mechanics observed on the macroscopic scale. For this purpose, we developed a bottom-up approach, in which Molecular Dynamics simulations are used to characterize the mechanical response of smaller constituents of silk, on the basis of which Finite Element models are devised to predict the mechanical behavior of whole silk fibers. The figures here show the pulling of a strand out of the crystalline unit of silk (right) and the subsequent stress distribution (left) within a silk crystal under load of the central beta-strand. A movie of the rupture of such a crystal is shown here.

One of our key findings has been that an extraordinary toughness can be reached only if the silk crystals, in contrast to the common notion of a random arrangement of these crystals in the fibers, should be assembled into lamellae (or ‘salami slices’) along the silk fibers. The reason is that such a higher ordering of the two phases relative to each other results in a more homogenous stress distribution, and thereby higher rupture stresses and strains.

Such an ordering is likely to come about, at least to some extent, during silk fiber spinning, being enhanced by the dimerization of silk proteins at their N/C-termini.

Our multi-scale approach allows to determine the structural parameters that are responsible for silk’s toughness. We were able to rationalize nature’s choice of crystallinity, poly-alanine sequence length, crystal cross-section and crystal arrangements. We are currently refining our model to take the plastic and viscoelastic deformation of silk into account.